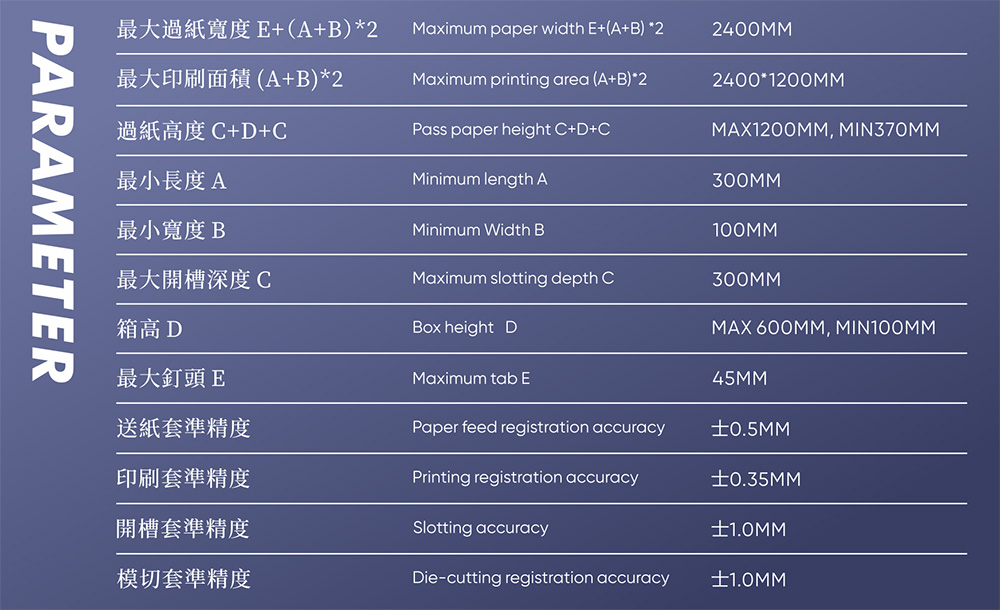

High Speed Four Color Printing Slotting And Die Cutting Machine (High Speed Series)

The entire machine is operated on a full touch screen and can be connected to the production management system, making the equipment more intelligent. lt adopts data input or order mode Managerial automatic adjustment, simple and convenient operation, fast order change, greatly saving operation labor and adjustment time.

Most electrical components are made of internationally renowned brands, mainly controlled by PLC computer technology, Touch screens are installed in the paper feeding section, printing section, and die-cutting section to store memory parameters.

The four axis leading edge roller vacuum adsorption paper feeding system is equipped with a frequency converter to adjust the vacuum pressure and adapt to different cardboard sizes and curved cardboard.

The use of keyless collars ensures high accuracy of printing chromatography without loosening the transmission gears and shafts during long-term use.

Modular design of the entire machine facilitates equipment upgrades.